NEWS

First, information from the waste situation

Waste is essentially an inverted image of the forming hole. The same part of the opposite position. By examining the scrap, you can determine whether the upper and lower die clearance is correct. If the gap is too large, the waste will appear rough, undulating fracture surface and a narrow bright band area. The greater the gap, the greater the angle between the fracture surface and the bright band. If the gap is too small, the waste will show a small angle fracture surface and a wide bright band area.

The large gap forms a hole with a larger roll edge and an edge tear, which gives the section a slight edge protrusion. A small gap forming band with slightly curled edges and large angles tear, causing the profile to be more or less perpendicular to the surface of the material.

An ideal waste should be reasonable and uniform light with collapse angle. Thus, the minimum thrust pressure can be maintained and a clean round hole with very little burr can be formed. From this point of view, by increasing the gap to extend the die life is at the expense of finished hole quality in exchange.

Two, the choice of mold clearance

The clearance of the die is related to the type and thickness of the material to be punched. Unreasonable clearances can cause the following problems:

(1) if the clearance is too large, the burr of the stamping workpiece is relatively large, and the quality of the stamping is poor. If the gap is too small, although the quality of the punch is better, but the wear of the mold is more serious, greatly reducing the service life of the die, and easy to cause the fracture of the punch.

(2) the gap is too large or too small, it is easy to produce adhesive on the punch material, resulting in stamping with material. A small gap makes it easy to form a vacuum between the bottom of the punch and the sheet metal, resulting in waste bounce.

(3) the reasonable gap can prolong the mould life, good discharging effect, reduce the burr and flanging plate, keep clean, consistent aperture do not scratch sheet, less grinding times, keep the flat sheet punching, accurate positioning.

Three, how to improve the service life of the mold?

For users, to improve the service life of die can greatly reduce the cost of stamping. The factors affecting the service life of the die are as follows:

1, the type and thickness of materials;

2, whether to choose a reasonable lower die clearance?;

3, the structure of the mold form;

4, material stamping is good lubrication?;

5, the mold has undergone special surface treatment?;

6, such as titanium, carbon titanium nitride;

7, up and down the tower of neutral;

8, adjust the reasonable use of gasket;

9. Is it suitable to use the oblique cutting edge die?;

10, machine tool base is worn?;

Four, stamping special size hole should pay attention to the problem

(1) punching with a minimum hole diameter of 0.8 - Phi 1.6 shall be done with a special punch.

(2) when punching the thick plate, please use the big number mold relative to the processing aperture. Note: at this point, if you use the usual size of the mold, will lead to damage to the thread of the punch.

(3) the proportion of the minimum width to the length of the punch edge should not be less than 1:10.

In 3 cases, rectangular punch, blade length 80mm, blade width is greater than or equal to 8mm the most appropriate.

(4) the relation between the minimum part size of the punch head and the plate thickness. It is recommended that the minimum part of the punch edge be 2 times the plate thickness.

Five 、 die sharpening

1, the importance of grinding die

Regular grinding die is the guarantee of punching quality consistency. The regular grinding die can not only improve the service life of the die, but also improve the service life of the machine, and the correct grinding time should be mastered.

2, the mold needs sharpening specific features

For the sharpening of the die, there is not a strict number of strikes to determine whether sharpening is necessary. It depends mainly on the sharpness of the edges. It is mainly determined by the following three factors:

(1) check the fillet of the blade. If the fillet radius reaches R0.1 mm (the maximum R value must not exceed 0.25 mm), sharpening is required.

(2) check the punching quality, is there a bigger burr?

(3) to determine whether sharpening is required by the noise of machine stamping. If the same die is stamped with abnormal noise, it shows that the punch is blunt and needs sharpening.

Note: the edge of the edge of the blade becomes rounded or the back of the blade is rough, and the edge grinding is also necessary.

3, grinding method

There are many ways to grind the die, which can be realized by special grinding machine or surface grinder. The frequency of the punch and die grinding is usually 4:1, and the height of the die is adjusted after grinding.

(1) the harm of incorrect grinding method: incorrect sharpening will aggravate the rapid destruction of the die edge, resulting in a great reduction in the number of striking each time.

(2) the benefits of the correct grinding method: regular grinding of the mold, the quality and accuracy of the punching can be stable. Die edge damage slower, longer life.

4, sharpening rules

The following factors should be taken into consideration when grinding the die:

(1) the blade rounding is in the case of R0.1-0.25 mm size, depending on the sharpness of the edge.

(2) the surface of the grinding wheel should be cleaned.

(3) a loose, coarse grain and soft grinding wheel is recommended. Such as WA46KV

(4) the amount of grinding time (depth) should not exceed 0.013 mm, grinding amount will cause overheating of the mold surface, the equivalent of annealing treatment, mold soft, greatly reduce the life of mold.

(5) sufficient coolant must be added during grinding.

(6) when grinding, the punch and the lower die must be kept firm and stable, and special jigs and fixtures are used.

(7) the amount of grinding of the die is certain. If the value is reached, the punch will be scrapped. If continue to use, easy to cause damage to the mold and machine, the loss outweighs the gain.

(8) after grinding, edge to stone processing, remove excessively sharp edges.

(9) after grinding, cleaning, demagnetization and oiling are necessary.

Note: the amount of grinding of the die depends mainly on the thickness of the sheet being punched.

Six, punch should pay attention to before use

1, storage

(1) clean the inner and outer parts of the upper mold with a clean cloth.

(2) take care of the surface without scratches or dents.

(3) oil and rust prevention.

2. Prepare before use

(1) thoroughly clean the upper die sleeve before use.

(2) to see if there is a scratch or dent in the surface. If yes, remove with whetstone.

(3) oiling both inside and outside.

3, the installation punch in the upper mold should pay attention to

(1) clean the punch and oil the long handle.

(2) insert the punch into the bottom of the upper die sleeve on the large station die, so that the punch can not be forced. Nylon hammer must not be used. When installing, the punch can not be fixed by tightening the bolt on the upper die sleeve, and the bolt can be tightened only when the punch is positioned properly.

4. Fit the upper die assembly into the turret

If the die life is to be extended, the gap between the outer diameter of the upper die sleeve and the turret hole shall be as small as possible. So please be careful with the following procedures.

(1) clean the keyway and inner diameter of the turret bore and oil it.

(2) adjust the keyway of the upper guide sleeve to match the key of the turret.

(3) insert the upper sleeve directly into the tower hole, and be careful not to have any inclination. The upper guide sleeve shall slide against the turret bore by its own weight.

(4) if the upper die sleeve is tilted to one side, it can be struck lightly with a soft tool, such as a nylon hammer. Repeat the percussion until the upper guide sleeve slides into the correct position by its own weight.

Note: do not apply the outside diameter of the upper guide sleeve, only press the top of the punch. Do not punch the top of the die sleeve to avoid damage to the turret hole and shorten the service life of the individual stations.

Seven, mold maintenance

If the punch is bitten by the material and cannot be removed, please check it as per the items listed below.

1, punch, lower die re sharpening. The cutting edge of the mold can make a beautiful cut section, the blade is blunt and requires extra punching pressure, and the rough section of the workpiece produces a great resistance, causing the punch to be bitten by the material.

2, mold clearance. If the clearance of the die is not properly chosen relative to the plate thickness, the punch needs a great deal of release force when it breaks away from the material. If this is the reason why the punch is bitten by the material, replace the lower die with reasonable clearance.

3, the status of processing materials. When the material is soiled or soiled, dirt attaches to the mold, which causes the punch to be bitten by the material and cannot be machined.

4, deformation of the material. The warp material clamps the punch after the punch is finished, causing the punch to bite. Warp material, please smooth and reprocess.

5, excessive use of spring. Will make the spring fatigue. Always pay attention to checking the performance of spring.

Eight, oiling

The amount of oil and the number of oiling are determined by the conditions of the material to be processed. Cold rolled steel plate, corrosion resistant steel plate, etc. no rust, no fouling material, to the mold

(3) the proportion of the minimum width to the length of the punch edge should not be less than 1:10.

(3) the proportion of the minimum width to the length of the punch edge should not be less than 1:10.

In 3 cases, rectangular punch, blade length 80mm, blade width is greater than or equal to 8mm the most appropriate.

(4) the relation between the minimum part size of the punch head and the plate thickness. It is recommended that the minimum part of the punch edge be 2 times the plate thickness.

Five 、 die sharpening

1, the importance of grinding die

Regular grinding die is the guarantee of punching quality consistency. The regular grinding die can not only improve the service life of the die, but also improve the service life of the machine, and the correct grinding time should be mastered.

2, the mold needs sharpening specific features

For the sharpening of the die, there is not a strict number of strikes to determine whether sharpening is necessary. It depends mainly on the sharpness of the edges. It is mainly determined by the following three factors:

(1) check the fillet of the blade. If the fillet radius reaches R0.1 mm (the maximum R value must not exceed 0.25 mm), sharpening is required.

(2) check the punching quality, is there a bigger burr?

(3) to determine whether sharpening is required by the noise of machine stamping. If the same die is stamped with abnormal noise, it shows that the punch is blunt and needs sharpening.

Note: the edge of the edge of the blade becomes rounded or the back of the blade is rough, and the edge grinding is also necessary.

3, grinding method

There are many ways to grind the die, which can be realized by special grinding machine or surface grinder. The frequency of the punch and die grinding is usually 4:1, and the height of the die is adjusted after grinding.

(1) the harm of incorrect grinding method: incorrect sharpening will aggravate the rapid destruction of the die edge, resulting in a great reduction in the number of striking each time.

(2) the benefits of the correct grinding method: regular grinding of the mold, the quality and accuracy of the punching can be stable. Die edge damage slower, longer life.

4, sharpening rules

The following factors should be taken into consideration when grinding the die:

(1) the blade rounding is in the case of R0.1-0.25 mm size, depending on the sharpness of the edge.

(2) the surface of the grinding wheel should be cleaned.

(3) a loose, coarse grain and soft grinding wheel is recommended. Such as WA46KV

(4) the amount of grinding time (depth) should not exceed 0.013 mm, grinding amount will cause overheating of the mold surface, the equivalent of annealing treatment, mold soft, greatly reduce the life of mold.

(5) sufficient coolant must be added during grinding.

(6) when grinding, the punch and the lower die must be kept firm and stable, and special jigs and fixtures are used.

(7) the amount of grinding of the die is certain. If the value is reached, the punch will be scrapped. If continue to use, easy to cause damage to the mold and machine, the loss outweighs the gain.

(8) after grinding, edge to stone processing, remove excessively sharp edges.

(9) after grinding, cleaning, demagnetization and oiling are necessary.

Note: the amount of grinding of the die depends mainly on the thickness of the sheet being punched.

Six, punch should pay attention to before use

1, storage

(1) clean the inner and outer parts of the upper mold with a clean cloth.

(2) take care of the surface without scratches or dents.

(3) oil and rust prevention.

2. Prepare before use

(1) thoroughly clean the upper die sleeve before use.

(2) to see if there is a scratch or dent in the surface. If yes, remove with whetstone.

(3) oiling both inside and outside.

3, the installation punch in the upper mold should pay attention to

(1) clean the punch and oil the long handle.

(2) insert the punch into the bottom of the upper die sleeve on the large station die, so that the punch can not be forced. Nylon hammer must not be used. When installing, the punch can not be fixed by tightening the bolt on the upper die sleeve, and the bolt can be tightened only when the punch is positioned properly.

4. Fit the upper die assembly into the turret

If the die life is to be extended, the gap between the outer diameter of the upper die sleeve and the turret hole shall be as small as possible. So please be careful with the following procedures.

(1) clean the keyway and inner diameter of the turret bore and oil it.

(2) adjust the keyway of the upper guide sleeve to match the key of the turret.

(3) insert the upper sleeve directly into the tower hole, and be careful not to have any inclination. The upper guide sleeve shall slide against the turret bore by its own weight.

(4) if the upper die sleeve is tilted to one side, it can be struck lightly with a soft tool, such as a nylon hammer. Repeat the percussion until the upper guide sleeve slides into the correct position by its own weight.

Note: do not apply the outside diameter of the upper guide sleeve, only press the top of the punch. Do not punch the top of the die sleeve to avoid damage to the turret hole and shorten the service life of the individual stations.

Seven, mold maintenance

If the punch is bitten by the material and cannot be removed, please check it as per the items listed below.

1, punch, lower die re sharpening. The cutting edge of the mold can make a beautiful cut section, the blade is blunt and requires extra punching pressure, and the rough section of the workpiece produces a great resistance, causing the punch to be bitten by the material.

2, mold clearance. If the clearance of the die is not properly chosen relative to the plate thickness, the punch needs a great deal of release force when it breaks away from the material. If this is the reason why the punch is bitten by the material, replace the lower die with reasonable clearance.

3, the status of processing materials. When the material is soiled or soiled, dirt attaches to the mold, which causes the punch to be bitten by the material and cannot be machined.

4, deformation of the material. The warp material clamps the punch after the punch is finished, causing the punch to bite. Warp material, please smooth and reprocess.

5, excessive use of spring. Will make the spring fatigue. Always pay attention to checking the performance of spring.

Eight, oiling

The amount of oil and the number of oiling are determined by the conditions of the material to be processed. Cold rolled steel plate, corrosion resistant steel plate, etc. no rust, no fouling material, to the mold

Ten, the use of special forming tools notice

1, different types of machine slider travel is different, so attention should be paid to the molding mold closure height adjustment.

2, must ensure that the molding is sufficient, so it needs careful adjustment, each adjustment amount is best not to exceed 0.15 mm, if the adjustment is too large, easy to cause damage to the machine and mold damage.

3, for stretching molding, please choose light spring components, to prevent the sheet of tear, or because of uneven deformation, unloading difficult.

4 、 the ball shaped support die is installed around the forming die to prevent the material from tilting.

5. The molding position shall be as far away from the clamps as possible.

6, forming the best processing program at the end of the implementation.

7, be sure to ensure good lubrication plate.

8, when ordering, pay attention to the special molding tools give way, and if the two molding distance is relatively close, please be sure to communicate with our company sales staff.

9, because the molding tool needs longer discharging time, therefore the molding process must use low speed, had better have the time delay.

Eleven, the use of rectangular cutting tool notes

1, as far as possible, larger than 80% of the total length of the tool.

2, it is best to jump through the programming step.

3, it is recommended to choose oblique blade mold.

Twelve, in the case of no more than the nominal machine, how to punch?

During production, a circular hole greater than 114.3mm diameter is needed. Such a large hole will exceed the nominal limit of the machine, especially for high shear strength materials. This method can be solved by punching out large size holes through multiple punching methods. With small molds, cutting along the perimeter of the big circle can reduce the punch pressure by half or more. In most of the molds you already have, most of the molds can do that.

Thirteen. A simple method for punching big holes

The die of this convex lens can be made into the radius size you need. If the bore exceeds the punch nominal force, we recommend the use (A) scheme. Use this mold to blow out of the circle. If the bore can be punched within the nominal range of the punch, a radial die and a convex lens die to punch out the required hole within four times without rotating the die (B)

Fourteen, and finally down shape

When forming dies, avoid down forming operations, as this will take up too much vertical space and lead to additional flat or bent plate processes. Down forming may also sink into the lower die and then be pulled out of the turret. However, if the down forming is the only technological choice, then it should be taken as the last step in the process of handling the sheet.

Fifteen, prevent material distortion

If you need to cut a large number of holes on the sheet and the sheet does not stay flat, the cause may be the cumulative stress on the punch. When a hole is punched, the material around the hole is pulled downward, so that the tensile stress on the upper surface of the plate increases. Undershoot movement also led to the lower surface of the plates increases the compressive stress. For a small number of holes, the result is not obvious, but with the increase of punching number, the tensile stress and compressive stress also increase exponentially until the plate deformation.

One way to eliminate this deformation is to punch the hole at each hole and return the remaining hole. Although this produces the same stress on the plate, it collapses the tensile stress / compressive stress produced by a continuous and successive tangential shear. Thus, the first batch of pores shared the deformation effect of the second batch of holes.

Sixteen, if your stainless steel flanging deformation

Before forming the flanging, a high quality forming lubricant is applied to the material, which allows the material to be separated from the mold better and smoothly to the lower die surface during forming. This gives the material a better chance to distribute the stresses generated by bending and stretching to prevent deformation at the edges of the formed flanging hole and abrasion at the bottom of the flanging hole.

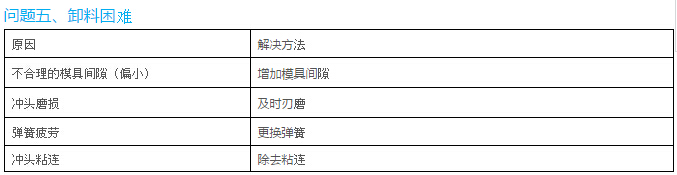

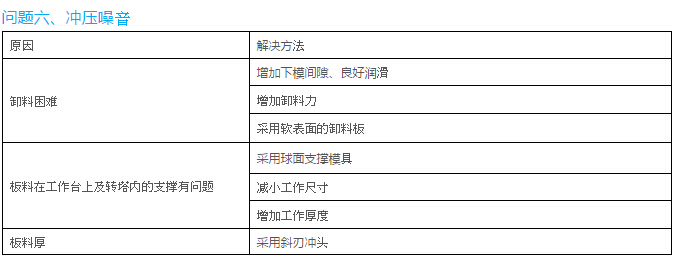

Seventeen, to overcome the difficulties of unloading a few suggestions

1. Use a punch with fine core particles.

2. Increase the clearance of the lower die.

3, check the degree of fatigue of the spring.

4 、 use heavy duty mold.

5, appropriate use of oblique blade mold.

6 、 lubrication plate.

7, the big station die need to install polyurethane material unloading.

Eighteen, the main cause of waste rebound

1, the sharpness of the edge. The greater the fillet, the more likely it is to bounce back the waste material.

2, the modulus of the mold. When the die is pressed, the requirement of the modulus is certain, the modulus is small, and it is easy to cause the scrap to rebound.

3, mold clearance is reasonable?. Unreasonable mold clearance, easy to cause waste rebound.

4, whether the surface of the processed plate is greasy or not.